Foundations of Remote Control for Counter Current Systems

Core architecture: columns, pumps, sensors, and flow regulators enabling remote operability

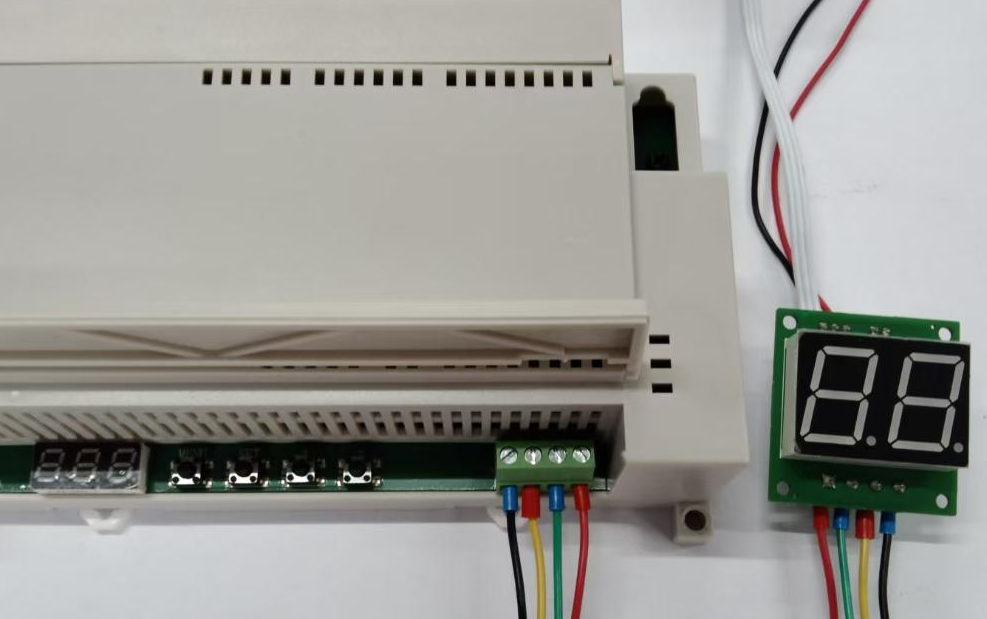

Counter current systems really rely on four main parts working together for good remote operation: separation columns, those precision pumps, inline sensors, plus flow regulators. The columns basically act as containers where chemicals get exchanged back and forth. Pumps handle moving fluids around in specific directions at controlled speeds. Inline sensors are constantly checking important stuff like pressure levels and how thick the fluid is, sending all that information to flow regulators which then make adjustments on the fly. What makes this whole setup work so well is that it creates a closed loop system, letting people operate everything from another location without needing to constantly check in. Take flow sensors for example they can spot changes even as tiny as plus or minus 2% away from what's supposed to happen, which triggers automatic corrections in the pump settings. Industry research shows these kinds of responsive systems cut down on the need for hands-on monitoring by about 40%, saving both time and money in real world operations.

Why deterministic control loops and low-latency feedback are essential for stable counter current operation

The deterministic nature of control loops means they provide consistent responses no matter what the system load is, which is really important when trying to maintain those concentration gradients in counter current processes. If there's too much delay in the feedback loop, we start seeing problems like phase separation. The rule of thumb is keeping feedback latency under 50 milliseconds. When delays go past this point, reaction dynamics get messed up. A study published last year found that when latency goes over 200ms, thermal transfer systems experience about a 15% jump in temperature overshoot, which definitely increases the chance of materials breaking down. Getting feedback down to around 20ms or better allows corrective measures to kick in before any disturbances spread throughout connected columns. This helps keep things flowing smoothly (laminar flow) and makes sure mass transfer works at maximum efficiency most of the time.

Industrial Automation Protocols for Counter Current System Remote Control

PLC integration: Modbus TCP and OPC UA for secure, real-time counter current system monitoring and actuation

PLCs play a key role in remote automation setups, using Modbus TCP and OPC UA protocols to keep an eye on operations and make adjustments in real time. For older equipment still running around plants everywhere, Modbus TCP offers good value while keeping data flowing reliably between pumps and flow control devices. The OPC UA protocol takes security seriously with encryption features and certificate checks, something most industrial folks now consider essential after all those recent cyber incidents. When everything is set up properly, these systems can respond within just a few milliseconds, which means no unexpected drops in flow that mess up separation processes. What makes OPC UA really stand out is its publish-subscribe approach that sends constant streams of sensor readings straight to the PLCs. This lets operators tweak pressure settings or adjust temperatures almost instantly when needed. Plants that have integrated these technologies report needing hands-on fixes about 40% less frequently compared to traditional setups.

SCADA and HMI solutions: centralized alarm management, historical trend replay, and responsive web-based remote access

SCADA systems give operators a single view over counter current processes, and HMIs offer easy to use web interfaces that work on both desktops and smartphones. The alarm management system puts priority on important issues like when pumps fail or pressure goes off track, which cuts down how long it takes to respond roughly half compared with old fashioned manual checks. Looking back at historical trends helps engineers spot problems that keep happening again and again, such as flow imbalances in the system. This kind of analysis supports better maintenance planning before equipment breaks down completely. Security measures include things like automatic logout after periods of inactivity plus multi factor authentication for login access. All these features let staff check out temperature readings or vibration patterns from anywhere they have internet connection, which means less downtime overall and smarter use of resources across different parts of the facility.

IoT and Cloud Enablement for Scalable Counter Current System Remote Operation

Edge-to-cloud data flow: MQTT gateways, time-series databases, and cloud-native control logic for distributed counter current systems

Remote operations at scale happen when we connect edge devices all the way up to cloud systems. MQTT gateways collect live information from various sensors around the facility. They gather things like flow rates, pressure differences, and temperature changes. Then they compress all this data so it can travel efficiently even on networks with limited bandwidth capacity. Once collected, these measurements get stored in special databases designed specifically for handling frequent industrial data streams. These databases allow analysis down to the millisecond level, helping spot problems with phase separation before they become serious issues. The cloud handles the actual control work using algorithms packaged in containers. It looks at all this sensor data and makes real time adjustments to pumps and valves located far apart from each other. When raw materials change unexpectedly, predictive models step in to tweak settings automatically, keeping everything running smoothly without needing anyone physically present onsite. The whole system works fast enough to make corrections within about 200 milliseconds and can handle thousands of processes happening simultaneously across multiple plants. Real world tests from 2023 show this setup cuts down unplanned stoppages by roughly 32% compared to older methods.

Cybersecurity and Operational Resilience in Remote Counter Current Control

OT-specific security: zero-trust segmentation, firmware integrity verification, and ISA/IEC 62443-aligned remote access controls

Security for Operational Technology (OT) systems needs special attention since these control the actual machinery running our factories, power grids, and water treatment plants. One effective approach is zero-trust segmentation which keeps vital components such as pumps and sensors separated from other network parts. This containment strategy stops attackers from moving freely once they breach the perimeter. Checking firmware integrity through cryptographic hashing techniques helps stop bad actors from running malicious code on equipment. When workers need remote access to these systems, following ISA/IEC 62443 guidelines becomes essential. These rules mandate secure connections via encrypted tunnels plus multi-factor authentication checks. According to research published by Ponemon Institute last year, implementing these security practices cuts down on successful intrusions by around two thirds in manufacturing facilities. What does this mean practically? Production lines stay operational even when faced with cyber attacks, minimizing downtime and protecting worker safety.

Remote diagnostics and predictive maintenance: vibration, thermal, and motor current signature analysis for counter current system health

When it comes to keeping machinery running smoothly, proactive health monitoring brings together vibration checks, thermal scans, and motor current readings to catch problems before they become major issues. The vibration sensors spot when bearings start wearing down on rotating parts, while thermal cameras pick up hot spots in flow control devices. Motor current analysis works differently but just as importantly it catches problems with electrical windings or uneven loads as they happen. According to the Reliability Solutions Report from last year, this combination method catches about 8 out of 10 potential failures in counter current systems, cutting unexpected breakdowns nearly in half. With automated warning systems in place, maintenance crews can tackle these issues right during planned maintenance windows instead of dealing with emergency repairs that disrupt production schedules.

Best Practices for Reliable Wireless and Secure Remote Access

Wireless protocol selection: LoRaWAN vs. Wi-Fi 6E for EMI-prone or hazardous environments hosting counter current systems

Selecting the proper wireless protocol really comes down to what kind of environment we're dealing with. For those electromagnetically noisy industrial settings, Wi-Fi 6E can deliver impressive speed through its 6 GHz band, but there's a catch it needs some serious shielding against all that interference. This makes it work well in places where things aren't dangerous and real time control matters most. However, if someone tries to install these systems in areas where explosions could happen, they'll face major costs for those special explosion proof enclosures. On the other hand, LoRaWAN operates at those lower sub-GHz frequencies and actually performs better in tough spots or far away locations. The signals can get through thick walls and structures while using very little power. What this means practically is that sensors powered by batteries can last for years without needing replacement. That's why many companies choose LoRaWAN when monitoring pumps from afar or gathering diagnostic information in places where safety standards require intrinsic protection against sparks or heat.

Access governance: MFA, session timeouts, and immutable audit logs aligned with NIST SP 800-82 Rev. 3

Remote access security needs multiple layers of protection. First off, multi-factor authentication checks who's actually logging in, beyond just a username and password. Then there are those 15 minute timeout rules that kick people out if they're not actively doing anything, which cuts down on accidental or intentional unauthorized access. The system also keeps detailed logs of all commands given to flow regulators and sensors, so we can look back at what happened during security breaches without worrying about someone altering the records later. All these measures follow guidelines from NIST SP 800-82 Rev. 3 basically. That document requires specific permission settings for different users and constant watch over the systems to stop things like stolen credentials or employees causing problems from within. It helps keep our counter current systems running safely over time.

FAQ Section

What are the main components essential for remote operation of counter current systems?

The key components include separation columns, precision pumps, inline sensors, and flow regulators.

Why is low latency feedback important in counter current systems?

Low latency feedback ensures timely corrective actions, preventing issues such as phase separation and improving system stability.

How do industrial automation protocols like Modbus TCP and OPC UA contribute to system security?

These protocols enable secure data flow, real-time monitoring, and quick adjustments, with OPC UA providing enhanced security through encryption and validation.

What roles do IoT and cloud technologies play in remote system operation?

They facilitate scalable, real-time data collection and control, enabling predictive adjustments, enhancing efficiency, and reducing operational costs.

How are cybersecurity measures implemented in OT systems?

These include zero-trust segmentation, firmware verification, and adherence to ISA/IEC 62443 standards to ensure secure remote access and system integrity.

Table of Contents

- Foundations of Remote Control for Counter Current Systems

- Industrial Automation Protocols for Counter Current System Remote Control

- IoT and Cloud Enablement for Scalable Counter Current System Remote Operation

- Cybersecurity and Operational Resilience in Remote Counter Current Control

- Best Practices for Reliable Wireless and Secure Remote Access

-

FAQ Section

- What are the main components essential for remote operation of counter current systems?

- Why is low latency feedback important in counter current systems?

- How do industrial automation protocols like Modbus TCP and OPC UA contribute to system security?

- What roles do IoT and cloud technologies play in remote system operation?

- How are cybersecurity measures implemented in OT systems?